How We Do?

Component Manufacturing Process Flow

Inspection Of Raw Material

In this stage engineer has to verify RMTC according to requirement.

Molding & DE flashing

In this stage molding is done according to approved parameters & extra flashes/runners is to be cut according to the master sample.

Final Inspection & Dispatch

In this stage 100% of inspection of the component is carried out & according to the customer requirement material is dispatched.

Tool Manufacturing Process Flow

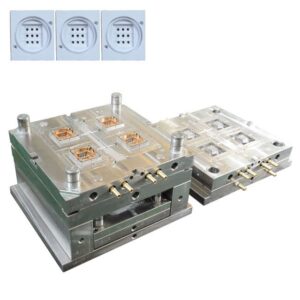

Requirement Gathering & Design

In this stage we collect detail requirement & design the tool as per the customer requirement by using various design software.

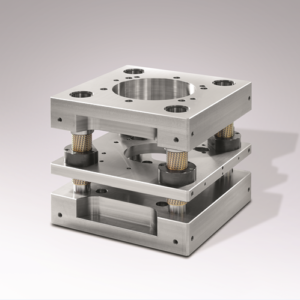

Machining & Assembly

In this stage according to APQP we are planning the activities which is to be done by VMC, CNC, EDM, etc. After this assembly is done with the proper tools.

Quality Inspection & Dispatch

Quality inspection is done by our expert team & manufactured tool is dispatched to the customer.

Want To Make A Smart Choice ?

Here We Deliver High Precision Molds & Engineering Works

Let us together build a product you dreamed .

So, if you are looking for the right company that’ll help you build a good product , we are right here!